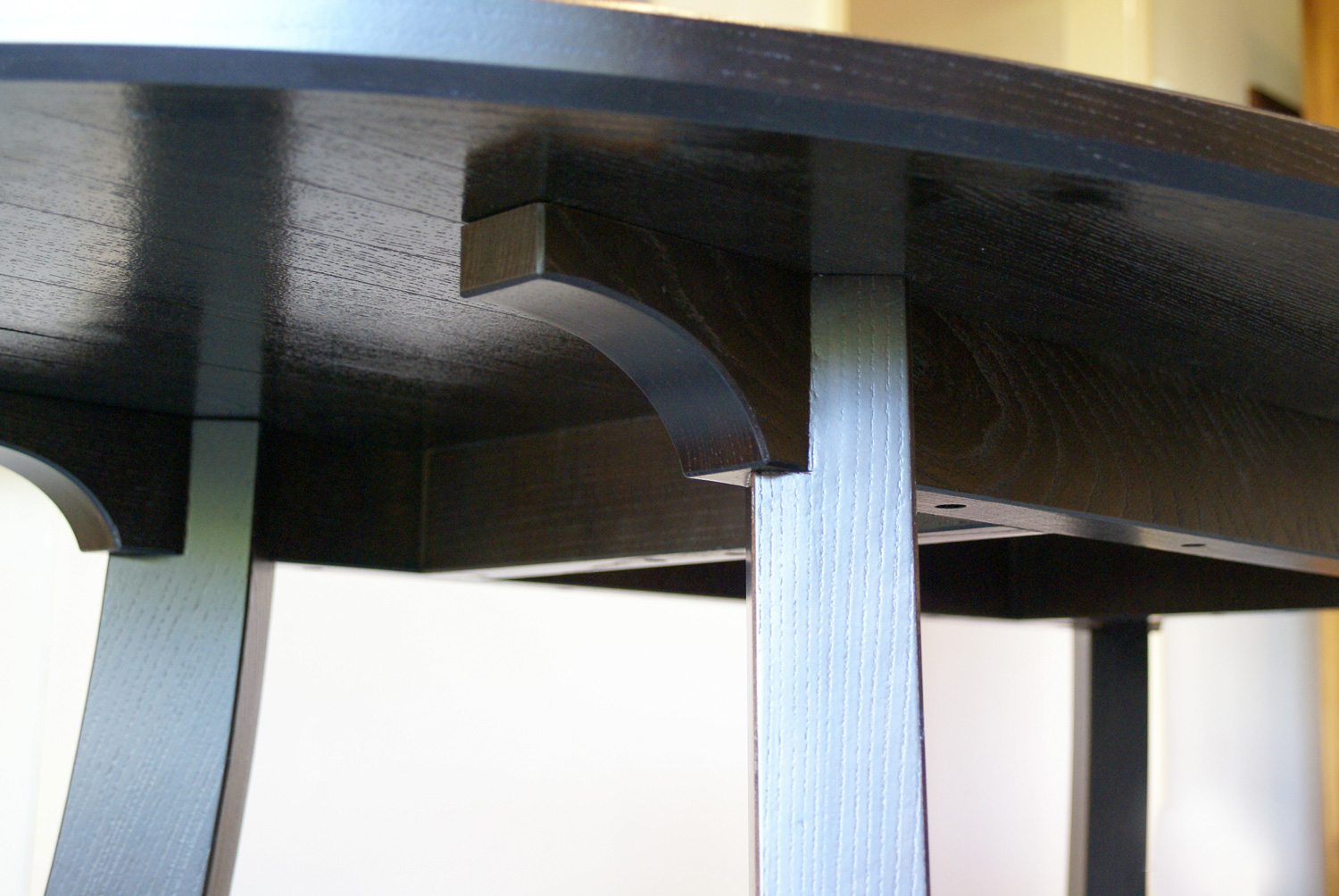

Sometimes it is tricky to make things look simple. It can be quite difficult to achieve that. This table is like that. To achieve a simple, uncluttered look, it had to have quite a complex joint for the table legs, and the table top had to be laminated so that it would not warp as it had very little support. There is an oriental influence to the design.

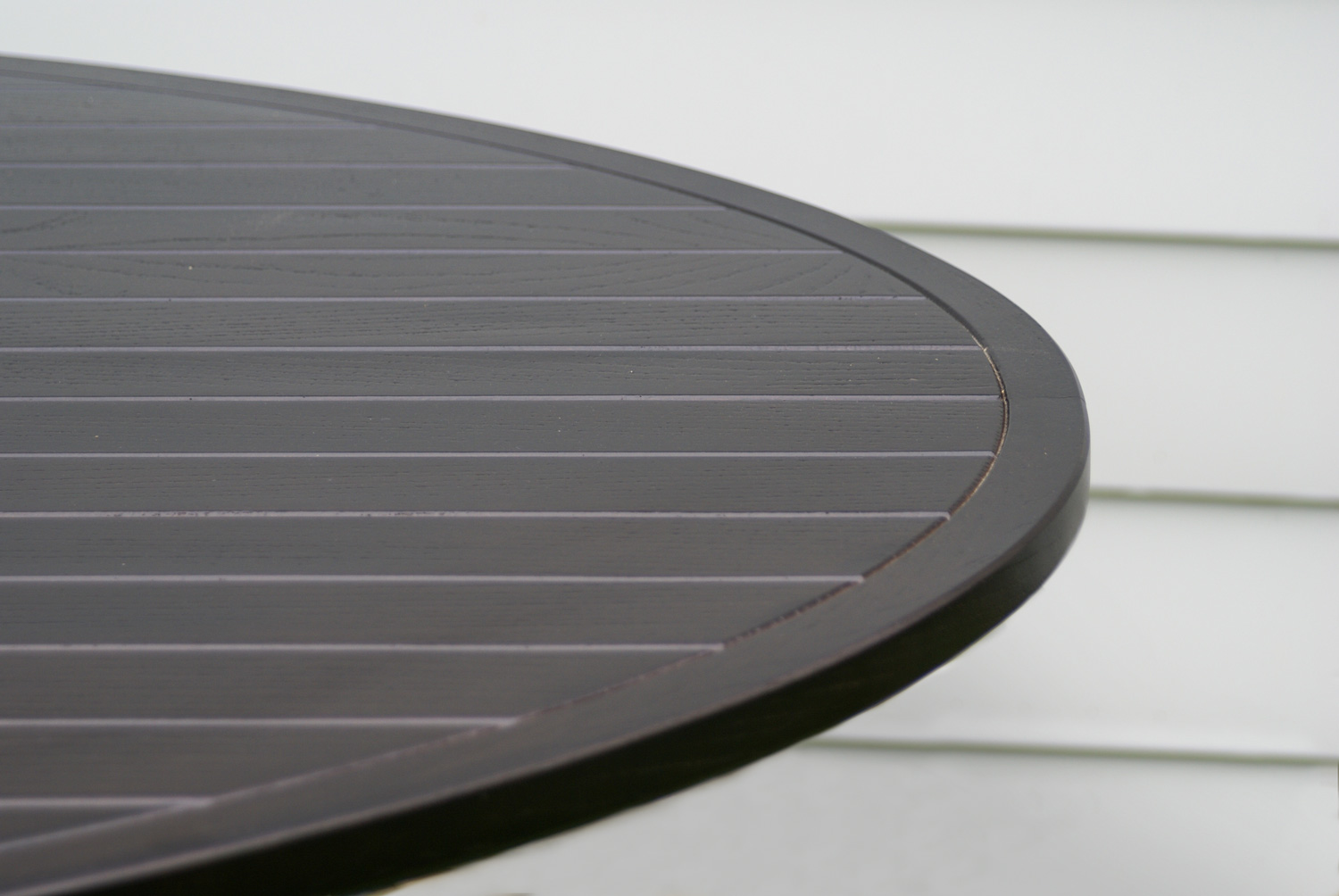

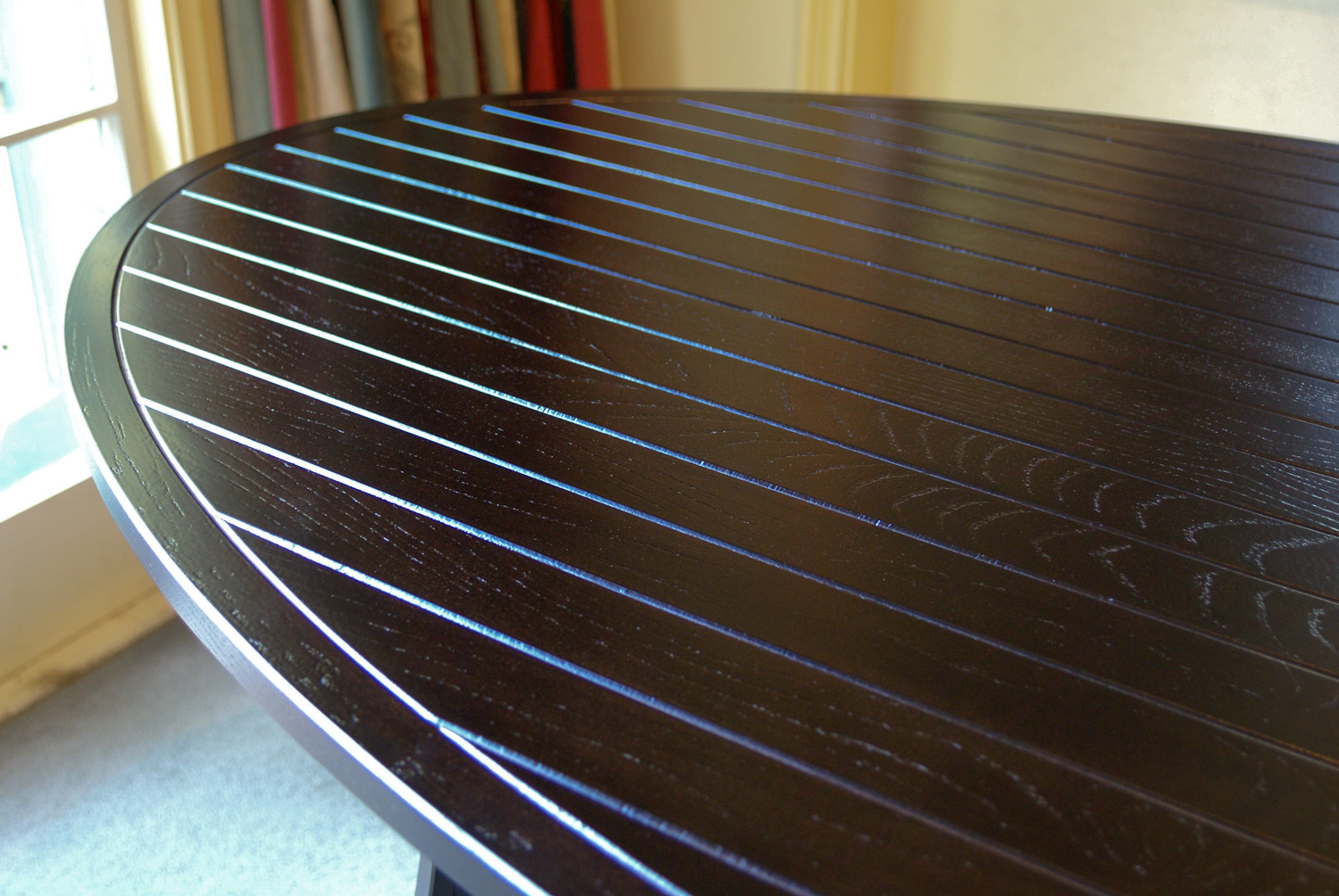

The finished stained table. Six seater elm dining table.

The first job was to cut out the components for the legs and framework of the table. Then came making the joints for the legs to the rails with a joint that was much more complex that you would normally have to do. This had to all be cut and shaped for the most part by hand. The cross rails were joined with a more conventional mortice and tenon type joint. Then I had to make up the top which was a laminated design of a layer of elm, then plywood, then another layer of elm. The outside edge (clashing) of the table was also laminated up from thin strips. This was to get the shape right and give it strength. I cut the shape for the jig on the CNC router and clamped up the clashing strip one quarter of the table at a time.

Progress shot of the leg join.

Click image for further detail photos.

The table was polished with a dark stain which was matched to a sample supplied by the customer. This was to match built in furniture.

Finished table showing curvature of the legs.